[ad_1]

“I believe I’m most likely simply as responsible as all people else,” Toyota Analysis Institute’s (TRI) senior vp of robotics, Max Bajracharya, admits. “It’s like, now our GPUs are higher. Oh, we received machine studying and now you understand we will do that. Oh, okay, perhaps that was tougher than we thought.”

Ambition is, after all, an essential side of this work. However there’s additionally a grand, inevitable custom of relearning errors. The neatest individuals within the room can let you know one million instances over why a particular concern hasn’t been solved, nevertheless it’s nonetheless simple to persuade your self that this time — with the fitting individuals and the fitting instruments — issues will simply be completely different.

Within the case of TRI’s in-house robotics crew, the unimaginable job is the house. The dearth of success within the class hasn’t been for lack of attempting. Generations of roboticists have agreed that there are many issues ready to be automated, however so far, successes have been restricted. Past the robotic vacuum, there’s been little in the way in which of breakthrough.

TRI’s robotics crew has lengthy made the house a main focus. That’s pushed, in no small half, by it selecting eldercare as a “north star” for a similar cause that Japanese corporations are thus far forward of the remainder of the world within the class. Japan has the world’s highest proportion of residents over the age of 65 — trailing solely Monaco, a microstate in Western Europe with a inhabitants of fewer than 40,000.

In a world the place our well being and wellness are so carefully tied to our skill to work, it’s a difficulty bordering on disaster. It’s the type of factor that will get Yale assistant professors New York Occasions headlines for suggesting mass suicide. That’s clearly essentially the most sensationalistic of “options,” nevertheless it’s nonetheless a difficulty in quest of significant answer. As such, many Japanese roboticists have turned to robotics and automation to deal with points like at-home healthcare, meals preparation and even loneliness.

Picture Credit: Brian Heater

Early, professionally produced movies showcased robotics within the house, executing complicated duties, like cooking and cleansing a broad vary of surfaces. When TRI opened the doorways of its South Bay labs to pick press this week to point out off a spread of its completely different initiatives, the house component was notably missing. Bajracharya showcased a pair of robots. The primary was a modified off-the-shelf arm that moved bins from a pile onto close by conveyer belts, in a demo designed for unloading vehicles — one of many harder duties to automate in an industrial warehouse setting.

The second was a wheel robotic that goes procuring. In contrast to the warehouse instance, which had normal components with a modified gripper, this method was largely designed in-house out of necessity. The robotic is distributed out to retrieve completely different merchandise on the shelf primarily based on bar codes and normal location. The system is ready to lengthen to the highest shelf to seek out objects, earlier than figuring out one of the best methodology for greedy the broad vary of various objects and dropping them into its basket. The system is an outgrowth of the crew’s pivot away from home-specific robots.

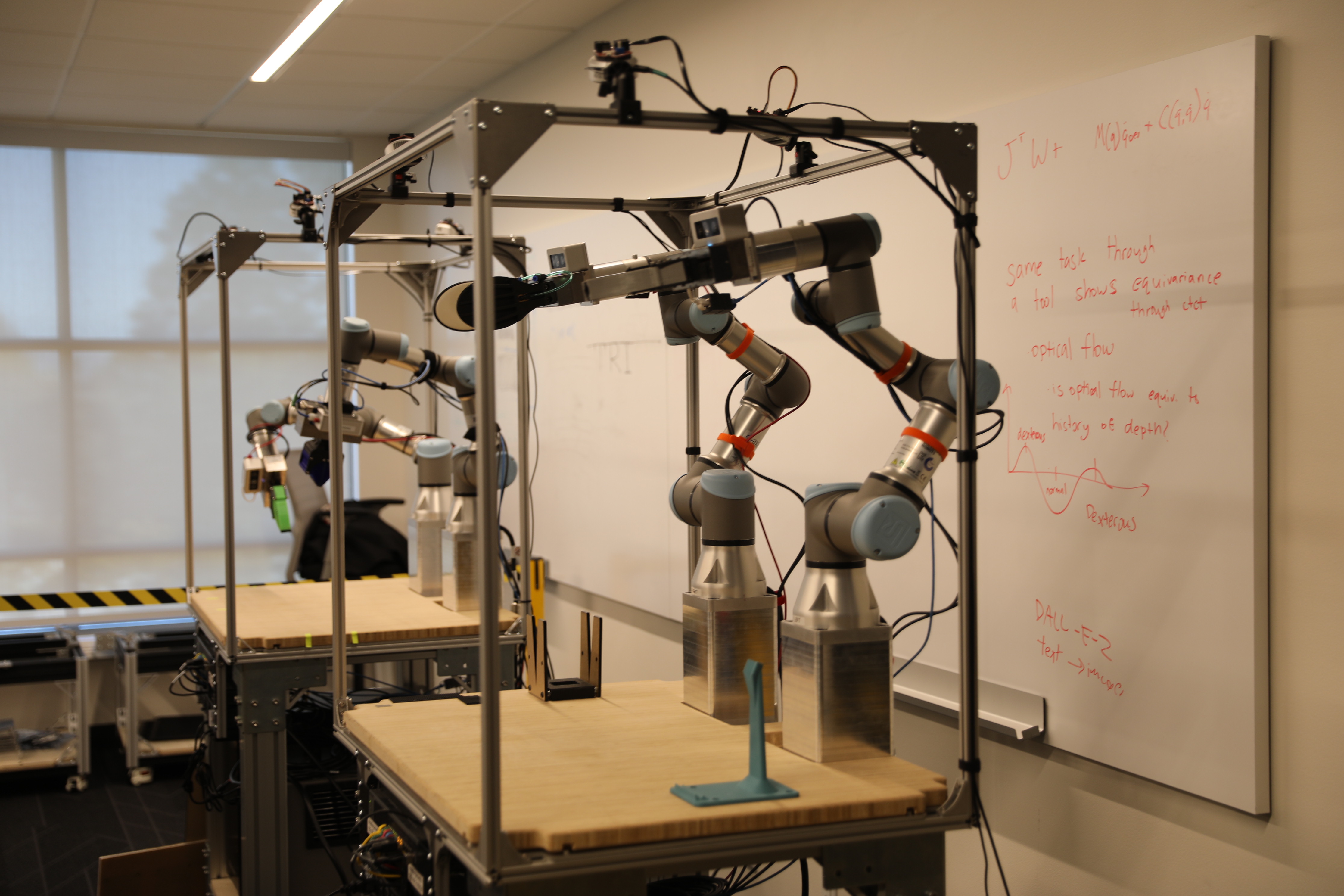

Picture Credit: Brian Heater

To the facet of each robots is a mock kitchen, with a gantry system configured to the highest of its partitions. A quasi-humanoid robotic hangs down, motionless and lifeless. It goes unacknowledged throughout the demos, however the system will look acquainted to anybody who has watched the crew’s early idea movies.

“The house is so arduous,” says Bajracharya. “We decide problem duties as a result of they’re arduous. The issue with the house will not be that it was too arduous. It was that it was too arduous to measure the progress we have been making. We tried a whole lot of issues. We tried procedurally making a large number. We’d put flour and rice on the tables and we’d attempt to wipe them up. We’d put issues all through the home to make the robotic tidy. We have been deploying into Airbnbs to see how nicely we have been doing, however the issue is we couldn’t get the identical house each time. But when we did, we might overfit to that house.”

Shifting into the grocery store was an effort to deal with a extra structured setting whereas nonetheless tackling a urgent concern for the aged neighborhood. In testing the product, the crew has moved from Airbnbs to a neighborhood mom-and-pop grocery retailer.

Picture Credit: Brian Heater

“To be completely sincere, the problem downside type of doesn’t matter,” Bajracharya explains. “The DARPA Robotics Challenges, these have been simply made up duties that have been arduous. That’s true of our problem duties, too. We like the house as a result of it’s consultant of the place we finally need to be serving to individuals within the house. But it surely doesn’t should be the house. The grocery market is an excellent illustration as a result of it has that vast variety.”

On this occasion, among the learnings introduced on this setting do translate to Toyota’s broader wants.

What, exactly, constitutes progress for a crew of this nature is a troublesome query to reply. It’s definitely one which’s high of thoughts, nonetheless, as massive companies have begun slicing roles in longtail analysis initiatives which have but to ship tangible, monetizable outcomes. Once I put the query to Gill Pratt yesterday, the TRI boss advised me:

Toyota is an organization that has tried very arduous to not have employment comply with enterprise cycle. The automobile enterprise is one which has booms and busts on a regular basis. Chances are you’ll know that the historical past of Toyota is to strive to not lay individuals off when instances are powerful, however as a substitute undergo a few issues. One is shared sacrifice, the place individuals take up the trigger. The second is to make use of these instances to spend money on upkeep, plans and training to assist individuals get skilled.

Picture Credit: Brian Heater

Toyota is well-known within the trade for its “no layoffs” coverage. It’s an admirable aim, definitely, particularly as corporations like Google and Amazon are within the midst of layoffs numbering within the tens of hundreds. However when targets are extra summary, as is the case with TRI and fellow analysis wings, how does an organization measure related milestones?

“We have been making progress on the house however not as quick and never as clearly as once we transfer to the grocery retailer,” the manager explains. “After we transfer to the grocery retailer, it actually turns into very evident how nicely you’re doing and what the actual issues are in your system. After which you possibly can actually give attention to fixing these issues. After we toured each logistics and manufacturing services of Toyota, we noticed all of those alternatives the place they’re principally the grocery procuring problem, besides slightly bit completely different. Now, as a substitute of the components being grocery objects, the components are all of the components in a distribution middle.”

As is the character of analysis initiatives, Bajracharya provides, generally the helpful outcomes are surprising: “The initiatives are nonetheless how we in the end amplify individuals of their houses. However over time, as we decide these problem duties, if issues trickle out which can be relevant to those different areas, that’s the place we’re utilizing these short-term milestones to point out the progress within the analysis that we’re making.”

The trail towards productizing such breakthroughs may also be fuzzy generally.

“I consider we type of perceive the panorama now,” Bajracharya. “Perhaps I used to be naive to start with considering that, okay, we simply want to seek out this individual that we’re going to throw the know-how over to a 3rd occasion or anyone within Toyota. However I believe what we’ve discovered is that, no matter it’s — whether or not it’s a enterprise unit, or an organization, or like a startup or a unit within Toyota — they don’t appear to exist.”

Spinning out startups — akin to what Alphabet has achieved with its X labs — is definitely on the desk, though it isn’t more likely to be the first path towards productization. What type that path will in the end take, nonetheless, stays unclear. Although robotics as a class is at present much more viable than it was when TRI was based in 2017.

“During the last 5 years, I really feel like we’ve made sufficient progress in that very difficult downside that we at the moment are beginning to see it flip into these real-world functions,” says Bajracharya. “We’ve got consciously shifted. We’re nonetheless 80% pushing the state-of-the-art with analysis, however we’ve now allotted perhaps 20% of our assets to determining if that analysis is perhaps pretty much as good as we expect it’s and if it may be utilized to real-world functions. We’d fail. We’d understand we thought we made some attention-grabbing breakthroughs, nevertheless it’s not anyplace close to dependable or quick sufficient. However we’re placing 20% of our effort towards attempting.”

[ad_2]